Rising customer demand for more sustainable metal effect architectural finishes has prompted AkzoNobel to develop patented particle technology for a new range of powder coatings.

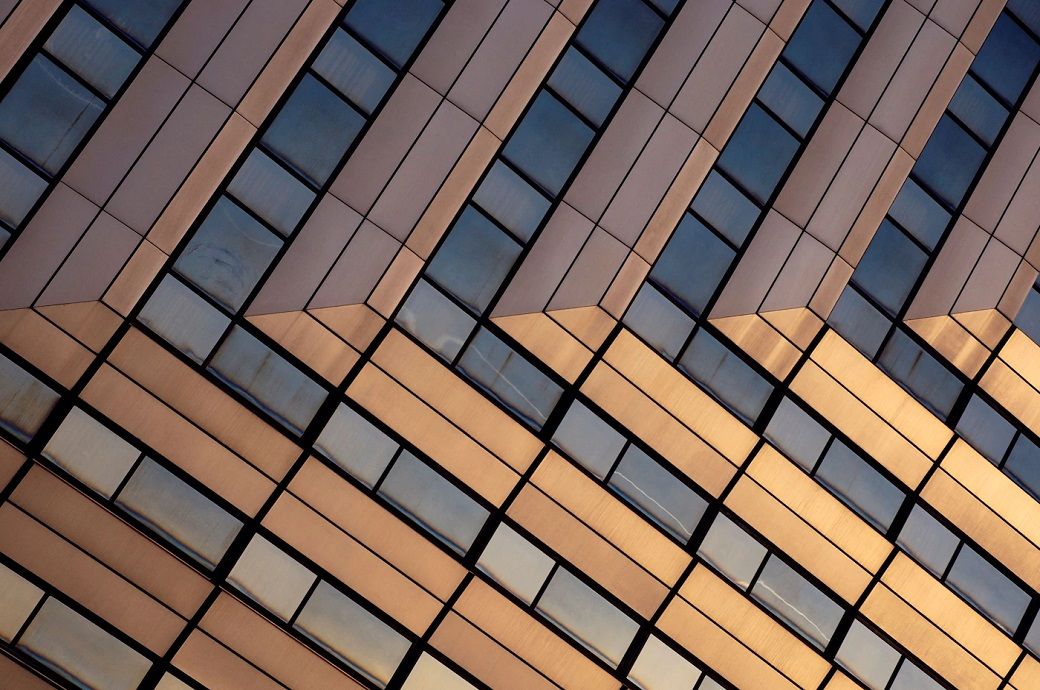

Having identified a clear market need, scientists at the company’s Powder Coatings business have created the Interpon D Natural Metals range. It has all the aesthetic beauty and durability that architects and designers are looking for – offering spectacular color and performance – but with none of the drawbacks of real metal.

The new collection features patented stabilized particulate technology which results in a more concentrated, deeper metallic finish than conventional metallic powder coatings.

“Our scientists and expert team of color specialists are at the forefront of innovation and creative excellence and are constantly working with and for our customers,” says Frank Vergeer, Research & Development director at AkzoNobel’s Powder Coatings business.

“With this new offering, we’re enabling architects and designers to not only reimagine how they can create a stunning metallic effect finish, but are also addressing their desire for a more sustainable world by overcoming the cost and practical handling considerations of using real metal.”

Designed to protect and enhance even in the most challenging environments, the new range features a broad palette of superdurable on-trend finishes, from copper, brass, steel and nickel through to silver and iron.

As with all Interpon products, it contains no volatile organic compounds (VOCs) and is more sustainable in application, since any overspray can be captured and reused, leaving virtually zero waste.

It’s the latest in a series of recent innovations from AkzoNobel’s Powder Coatings business, which have included the company’s first single layer powder coating for two-wheelers (Interpon A300) and an industry-first architectural powder coating which can be cured at temperatures as low as 150?C (Interpon D1036 Low-E and Interpon D2525 Low-E).

Fibre2Fashion News Desk (HU)