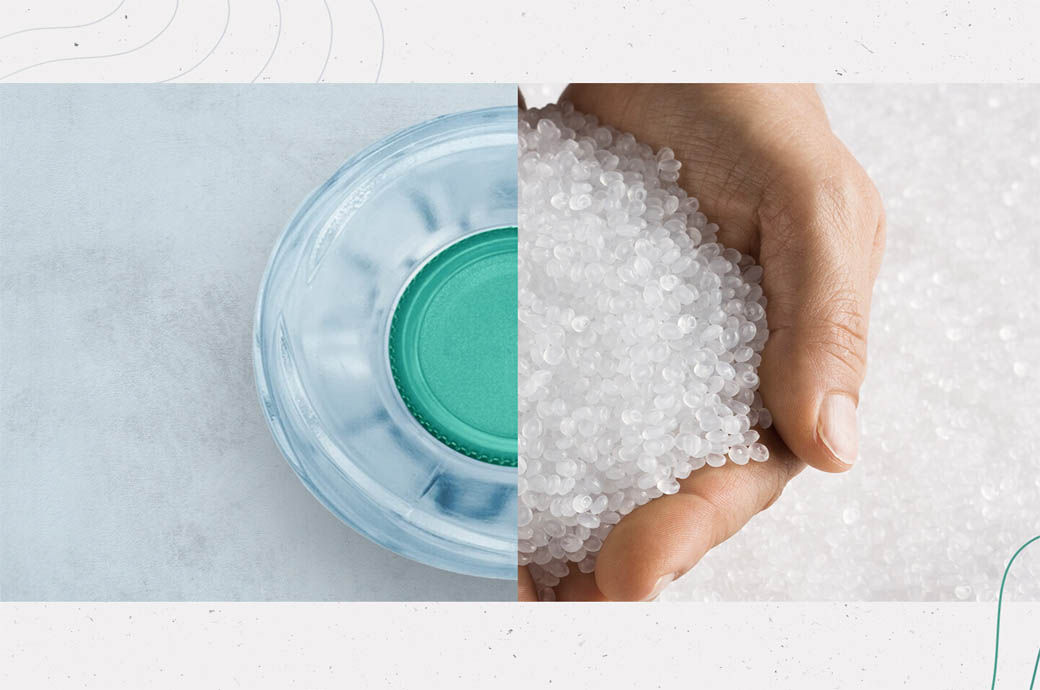

Powder coating is a solvent-free, low-waste technology, which can now be made more circular by including recycled content. Arkema's new recycled based powder resin innovation uses post-consumer PET (Polyethylene terephthalate) coming from end-of-life packaging as an alternative to traditional fossil based raw materials to create products containing up to 40% recycled PET and reducing PCF (Product Carbon Footprint) by up to 20%.

ENSURING HIGH PERFORMANCE AND MORE SUSTAINABLE LIFESTYLE

"Alongside our Bio-based and Mass Balance offers, increasingly incorporating recycled feedstocks is another step towards ensuring more circular high-performance solutions and a more sustainable lifestyle. Arkema's new recycled based powder resins further enrich sustainable solutions for our partners, enabling end markets to increase the percentage of recycled content in their finished products," said Richard Jenkins, Sr. Vice President, and member of the Executive Committee.

Building on its unique set of expertise in materials science, Arkema offers a portfolio of first-class technologies to address ever-growing demand for new and sustainable materials. With the ambition to become a pure player in Specialty Materials, the Group is structured into 3 complementary, resilient and highly innovative segments dedicated to Specialty Materials - Adhesive Solutions, Advanced Materials, and Coating Solutions - accounting for some 92% of Group sales in 2023, and a well-positioned and competitive Intermediates segment. Arkema offers cutting-edge technological solutions to meet the challenges of, among other things, new energies, access to water, recycling, urbanization and mobility, and fosters a permanent dialogue with all its stakeholders. The Group reported sales of around € 9.5 billion in 2023, and operates in some 55 countries with 21,100 employees worldwide.

Fibre2Fashion News Desk (RM)