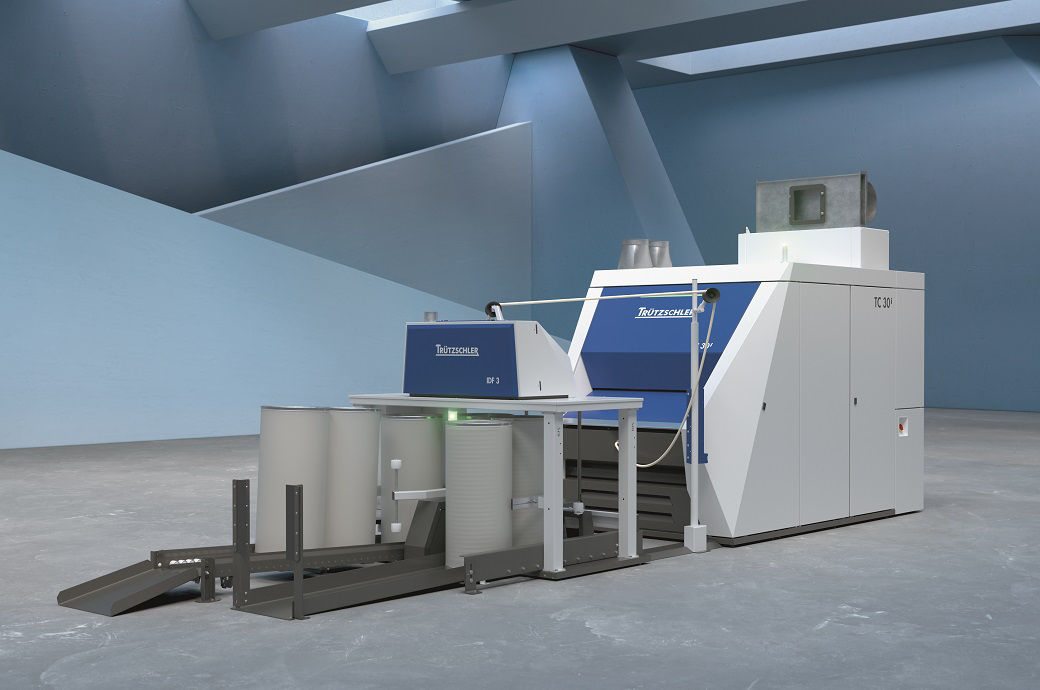

Trutzschler Spinning is showcasing innovations for carding, draw frame, and combing which meet the most important customer requirements in fibre processing: higher efficiency, more sustainable raw material utilisation, and intelligent automation—while also displaying the potential of digital technologies for spinning mills. Visitors can also look forward to the introduction of Trutzschler’s new brand Truecycled for textile recycling. The company’s machinery expertise and technological know-how enable its customers to produce sliver with the highest possible level of quality and make it possible to turn waste into value.

Furthermore, Trutzschler Card Clothing (TCC) is presenting a wide range of technologies from its clothing portfolio, which covers the complete spectrum of applications in the spinning and nonwoven markets. This includes all of the service features and machinery equipment that are supported, which are being demonstrated live at the booth as part of an ‘Action Point’ presentation. TCC is also focusing on recycling applications and showcasing its contribution to sustainability in the textile industry. These features and functions are all supplemented by ‘My Wires’, Trutzschler’s digital wire performance solution that is integrated into the Trutzschler digital platform, the company said in a press release.

Trutzschler Nonwovens is focussing on solutions that take nonwoven production processes to a new level. The story of innovations for needle-punching is being told at two booths. Trutzschler is focussed on the holistic T-Suprema package of excellent machinery, tailormade production lines, integrated digital support, and global service. The company’s cooperation partner in needle-punching, the Italian company Texnology Srl, is offering details about machinery and applications at booth A101 in Hall 10, and is also providing a chance to check out a running needle-punching line featuring some of the T-Suprema machinery.

The company’s nonwoven’s segment is also showcasing solutions for new and environmentally friendly wipe materials, as well as an innovative drying concept. Unlocking the potential of digitalisation is the key topic at the T-ONE corner, where experts are demonstrating every aspect of our digital environment—from quality control and recipe management through to real-time process monitoring and AI-based line optimisation.

Lastly, Trutzschler Man-Made Fibers is demonstrating the power of Optima, Trutzschler Man-Made Fiber’s flexible platform for all types of bulk continuous filament (BCF) carpet and industrial yarn (IDY).

Fibre2Fashion News Desk (DP)