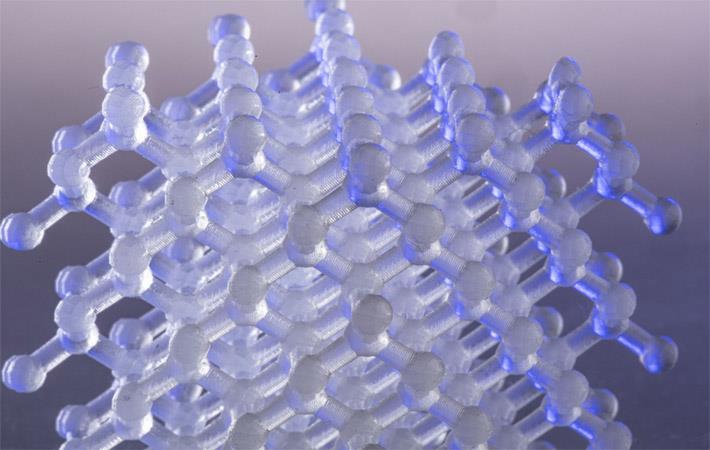

A global manufacturer of specialty chemicals, Huntsman, has unveiled details of a range of additive manufacturing materials that it has developed, which will address emerging needs in the 3D printing industry. Huntsman’s IROPRINT additive manufacturing platform contains three different kinds of urethane-based materials (resins, powders, and filaments).

The urethane-based materials can be 3D printed using a variety of additive manufacturing methods including stereolithography (SLA), high speed sintering (HSS) and fused filament fabrication (FFF). Initially, Huntsman is launching its range of soft, flexible IROPRINT additive manufacturing materials in the global footwear and sports industry, where 3D printing is being used to make both customised and mass manufactured shoes. Longer-term, Huntsman plans to roll its IROPRINT additive manufacturing platform out across a much wider range of applications and industries, the company said in a media statement.A global manufacturer of specialty chemicals, Huntsman, has unveiled details of a range of additive manufacturing materials that it has developed, which will address emerging needs in the 3D printing industry. Huntsman's IROPRINT additive manufacturing platform contains three different kinds of urethane-based materials (resins, powders, and filaments).#

At present, the IROPRINT additive manufacturing platform includes three product lines, which have been optimised to work with the main 3D printing techniques preferred by footwear producers.

IROPRINT R resins are a range of soft, durable, one-component liquid resin systems that can be 3D printed using SLA, digital light processing (DLP) and other radiation-curing methods. For companies looking to 3D print with powder-based materials, IROPRINT P powders are a line of high performance thermoplastic polyurethanes (TPU) for HSS forms of printing. IROPRINT F filaments are a collection of high performance TPU materials, which have a consistent diameter, and are designed for use with fused filament fabrication (FFF) and other extrusion-based printing techniques.

All three IROPRINT additive manufacturing product lines have been optimised for the production of footwear components and are easy to use and print, offering advanced abrasion resistance, elongation and tear strength. For radiation-cured forms of printing such as SLA or DLP, IROPRINT R resins also offer a long pot life and quick cure capabilities.

“Our innovation incubation team worked in close cooperation with end-users and industry leaders to develop our IROPRINT additive manufacturing product portfolio. Together, we looked closely at what makes a good 3D printing material, and what’s been missing from the market to date. We believe the launch of our IROPRINT additive manufacturing portfolio fills a gap that exists for a range of functional, durable, yet softer 3D printing materials, which are technology agnostic, and both economical and easy to print - whatever your preferred production technique,” Stephane Peysson, global business development manager at Huntsman polyurethanes said. (GK)

Fibre2Fashion News Desk – India