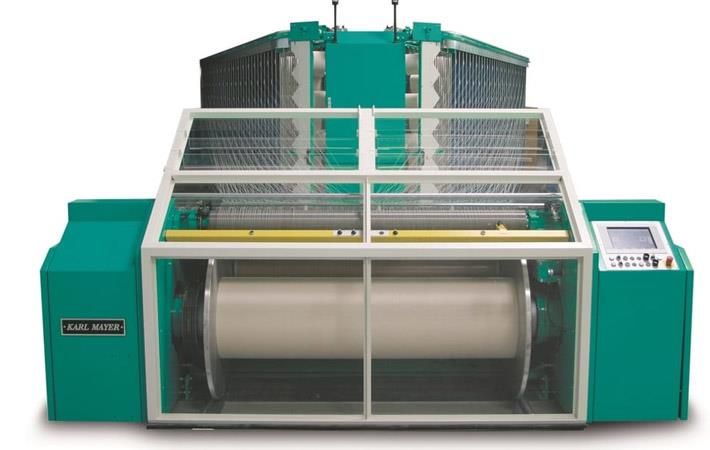

Karl Mayer, a market leader as well as driving force for innovations in textile machinery building, has unveiled the new WKD-SP direct warping machine. The machine uses large sectional warp beams to produce warp-knitted cotton terry towels efficiently. It is based on the Warpdirect machine for the weaving sector, and processes staple-fibre yarns.

Karl Mayer develops and manufactures high-performance warp preparation machines for both weaving and warp knitting and, in order to do this, uses the synergies that exist between the two sectors. The WKD-SP is the latest result of this know-how and technology transfer. Producers of warp-knitted, cotton terry towels should find this particularly interesting. This new machine delivers all the performance features of its predecessor but, above all, its advantages can be exploited by using back beams, with their wider widths, as sectional warp beams (SWBs) in the warp knitting sector.Karl Mayer, a market leader as well as driving force for innovations in textile machinery building, has unveiled the new WKD-SP direct warping machine. The machine uses large sectional warp beams to produce warp-knitted cotton terry towels efficiently. It is based on the Warpdirect machine for the weaving sector, and processes staple-fibre yarns.#

Die WARPDIRECT is a universal direct warping machine for processing every type of staple-fibre yarn. It produces high-quality beams for the slasher dyeing process in denim dyeing, for combining all the yarns on the warp beams on the assembling machine, and for processing in a sizing machine with subsequent warp beam production. The back beams for these various processes are of the highest quality. The beams are completely cylindrical, thanks to an intelligent press roller system and optimum yarn laying, and the yarns are arranged extremely accurately. A computer-controlled length measuring system delivers a length accuracy of 0.1 per cent. The yarns are also handled very gently. Other advantages of the WARPDIRECT include its low maintenance costs and high productivity. The maximum warping speed is 1,200 m/min. The easy-to-use, graphic touchscreen guarantees optimum machine usage.

The starting point for modifying the WARPDIRECT to create the WKD-SP were the demands made by the TM 4 TS EL during use. An efficient direct warping machine was needed to match this efficient machine for producing warp-knitted cotton terry towels. The modifications that were needed relate mainly to the software. The program changes enable constant yarn tension levels and completely uniform SWB circumferences to be produced. SWBs with the same circumferences and yarn tension levels are needed, since several of them are processed at the same time on the TM 4 TS EL.

The SWBs of the new direct warping machine have the same width as back beams. This means that the number can be reduced when loading the machine, and the direct beaming process becomes more efficient. (GK)

Fibre2Fashion News Desk – India