In contrast to a conventional dyeing process, the colours can be reproduced exactly. Besides the usually lower production costs and a shorter throughput time, this is one of the main advantages for the further processing chain.

The environment is, however, the main beneficiary of the ‘Clean Color Concept’. The addition of colour directly into the spinning mass saves up to 50 per cent of colour pigments. Further chemicals, energy and above all an enormous amount of waste water from a conventional dyeing process are completely omitted thanks to this technology.

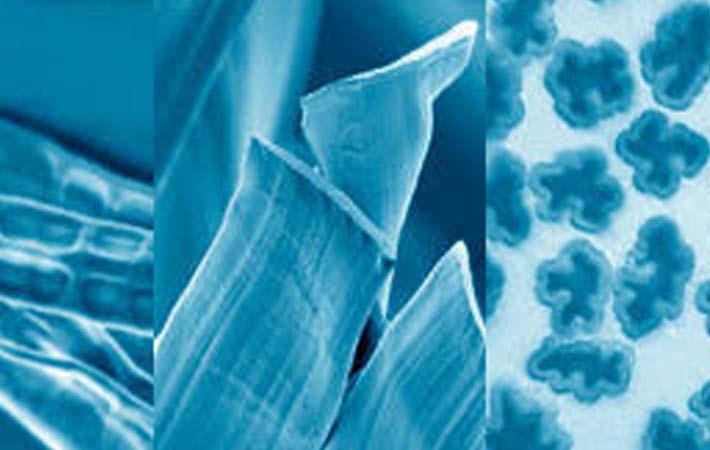

Textiles made from a blend of spun dyed polyester and viscose fibres combine the advantages of both fibres. They are easy to care and dimensionally stable, yet feel pleasantly soft on the skin and offer high wearer comfort. They are ideally suited for all applications that need large quantities of fabric of a precisely defined shade and that must deliver comfort and wear qualities as for example professional clothing or uniforms, but also furnishing or upholstery fabrics. (GK)

Fibre2Fashion News Desk – India