Mayer Braidtech, a wholly-owned company subsidiary, has announced that it has merged with Mayer & Cie. Braiding machine production and sales will be a separate division of the former parent company. With this move, the circular knitting machine manufacturer has formally completed the integration of Mayer Braidtech at the company’s Albstadt headquarters.

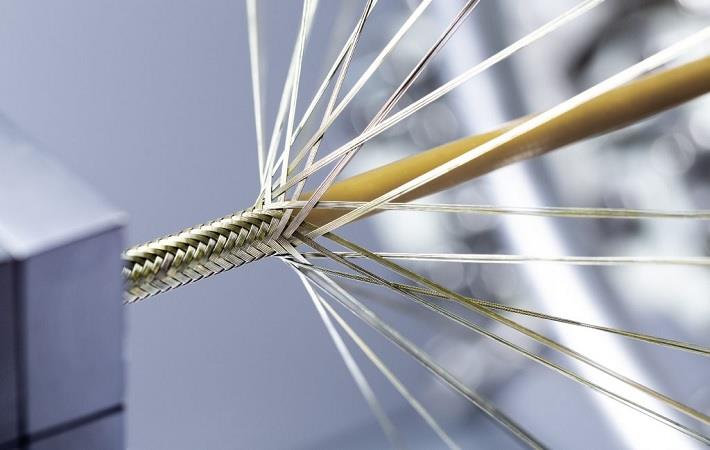

Mayer & Cie. has implemented various further developments since the machines have been made in Albstadt. The most important is the improved drive system, which is operated and controlled via a servomotor. Each deck of a double- or triple-deck braiding machine is driven separately. Braiding machines are to continue to be further developed and optimised. The division has its own development department where several designers are working on improvements. The team has already applied for a patent for the revision of a module, the company said in a press release.Mayer Braidtech, a wholly-owned company subsidiary, has announced that it has merged with Mayer & Cie. Braiding machine production and sales will be a separate division of the former parent company. With this move, the circular knitting machine manufacturer has formally completed the integration of Mayer Braidtech at the company's Albstadt headquarters.#

Mayer & Cie.’s portfolio currently consists of seven different types of braiding machine. The Albstadt pilot series of six of them have been manufactured over the past two years. All of them are available in single-, double- or triple-deck versions. Customers can also configure their braider lines individually. The acoustic protection booth, for example, is available on demand with either a swing or a sliding door. Mayer & Cie. Braidtech’s most popular model is the MR15-24 Carrier, which has accounted for more than half of the machines made and sold over the past two years.

“By integrating Mayer Braidtech into Mayer & Cie., we have formally completed a process that for us has long been accomplished on a day-to-day work basis. We definitely benefit from one another, be it in manpower, logistics or simply in sharing news and views. We have thereby laid a firm foundation for the further development of our machines to meet market requirements. The MR15-24 Carrier is a very flexible machine. Hoses large and small can be braided on it. A special machine like an MR15-18 Carrier is more productive for making small hoses, for example, but the MR15-24 Carrier can be put to a wider range of uses,” Patrick Moser, managing director of Mayer Braidtech and future head of Mayer & Cie.’s braiding division said.

Fibre2Fashion News Desk (GK)