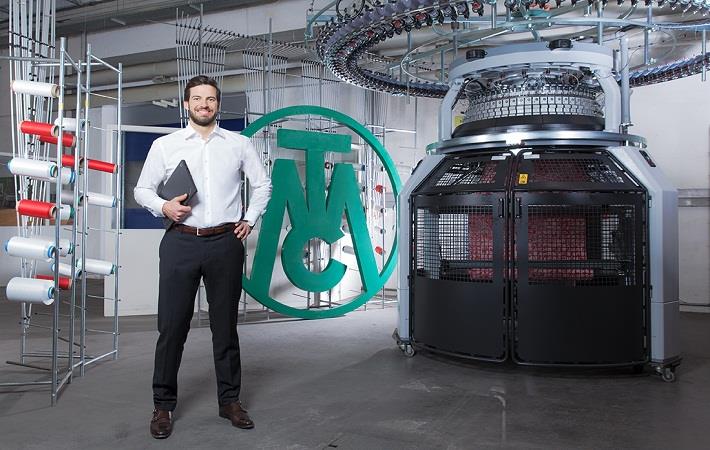

“There is no such thing as digitisation per se. There are different areas in which it can be of relevance for us as an engineering company. They include, for example, digitisation of production and the value chain, better known as Industry 4.0, digitisation of the organisation and of collaboration, and digitisation of the product itself. Each angle has different challenges and benefits. Within this framework every company must decide for itself what makes sense and when,” said Sebastian Mayer, a member of the Mayer & Cie management and in charge of corporate development, in a company press release.

A key concern at Mayer & Cie is to take a closer look at existing processes and see how they can be mapped more efficiently and at less expense.

Mayer & Cie has already taken the first step: identifying approaches that are meaningful and relevant for the company. They consist mainly of ensuring data quality and continuity on the basis of sustainable future-oriented technologies. Specifically that means, systematically collecting circular knitting machine data. Data continuity and the seamless automated flow of collected data to its destination without perceptible interruptions play a special role.

“The classic example of discontinuity is the excel spreadsheet that one employee feeds with data he has collected from an existing database in order to send it to a colleague who then inputs it by hand into another system,” said Mayer.

There is another Mayer-specific component where data continuity is concerned. The company has employees working for more than 40 years with it. So there is an enormous amount of ‘head knowledge’ around. “Think of employees who started at the firm as fitters over 30 years ago and are now performing management tasks. They are walking encyclopaedias of machine and customer knowledge. This valuable knowledge ought to be readily accessible for all employees,” said Mayer. The digitisation endeavours at Mayer & Cie is set to benefit the company from a better overall customer experience and from even more specific advice.

Mayer & Cie has laid the technical groundwork for change by introducing a new ERP system. It is the indispensable basis for all other services that the company would like to provide and central hub for all data and information flows.

The company’s next target is specific measures to improve customer satisfaction. They include ways to provide remote technical support, better known as remote services. Knitting machines from Mayer & Cie are all over the world. Even though the circular knitting machine manufacturer has about 80 agencies around the world it can take days for the nearest service engineer to call on the customer. That is too long and is often not necessary.

“We are working inter alia on solutions that involve mixed-reality glasses,” said Mayer. “They enable us to see what the customer sees without the need for protracted explanations. Everyone who has ever described a technical problem over the telephone knows just how arduous that can be.”

Using mixed-reality glasses, customers can be shown remotely how to carry out regular maintenance work and even simple repairs. A web shop from which customers can order consumables and spare parts irrespective of opening hours or language barriers is also about to be launched. In future, all these measures will lead to a comprehensive customer portal where customers can access centrally anything they need to know about their machines and communicate with Mayer & Cie or its representatives. Maintenance might also be managed via this portal, with predictive maintenance as the keyword. (PC)

Fibre2Fashion News Desk – India