Textile and clothing producers are clutching their heads in disbelief. The EU requires companies to produce sustainably, respect human rights at every stage, use materials and machinery with the most negligible environmental impact, and extend products’ life. How can one meet the legal requirements while maintaining production in Europe, where wages are high, and textile workers are in short supply?

There is just one answer: AI

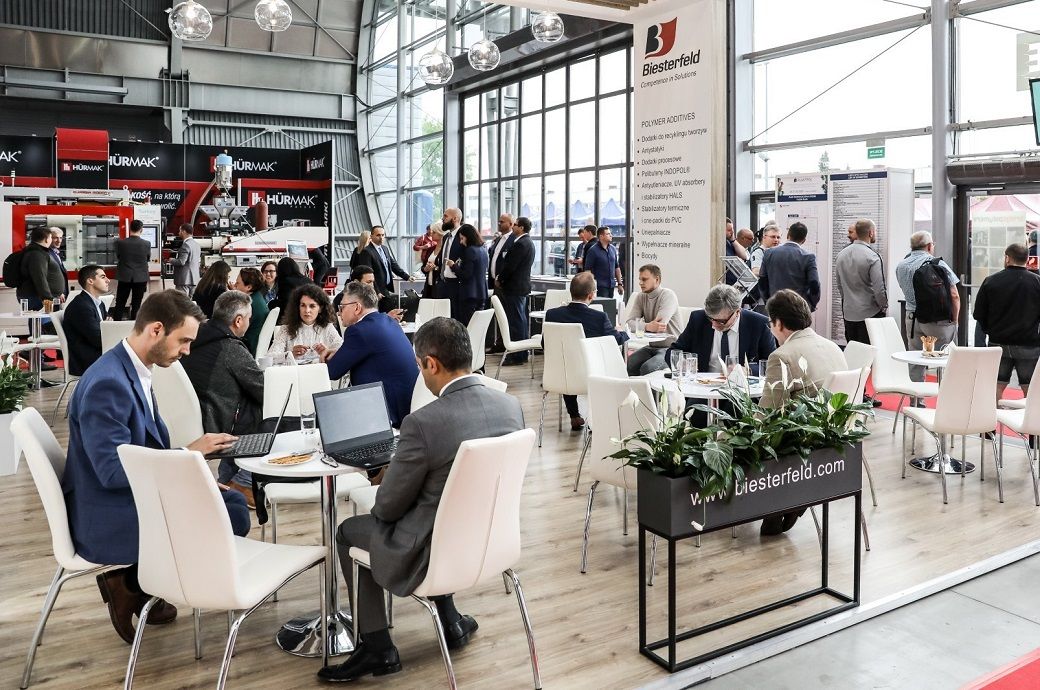

Experts in fabric and clothing production unanimously say that we should automate most of the factory processes or we cannot count on business development and profits. Thus Targi Kielce, one of Poland’s leading organisers of B2B events, created the platform for presenting AI tools for textile production, a showcase for modern textile machines.

- Targi Kielce helps arrange a new textile reality in Poland. (…) My TexStyle exhibitors and representatives of the Polish and foreign textile industries and scientific milieus will present completely new technological solutions. The show is an opportunity for expo visitors to become familiar with innovative devices. Manufacturers find their bearings in a new technological world. – says Henryk Marucha, owner of Victory Sportswear Company.

The International Expo of Textile Machines, Materials and Accessories MyTextile is held from 7 to 9 May 2025 in the Kielce Exhibition and Congress Centre. The event brings together exhibitors from five continents - companies from Italy, Spain, Portugal, Germany, Switzerland, Turkey, Uzbekistan, China, India and Poland present their products.

What makes My Texstyle complete?

The exhibition is divided into 8 thematic zones. Seven intended for the exhibitors of the following industries: machinery, fabrics, accessories, laboratory, textile chemicals, recycling, innovations and Start-ups Zone. The last Knowledge Zone is Future TexStyle Congress, the accompanying event of the fair.

My TexStyle participants can see the offers of companies presenting textile machines, sewing machines, cutters, 3D printers, fabrics, knitwear, yarn fibres, laboratory equipment, advanced machines for textile recycling and dyes and a plethora of other products and services.

The three-day Future TexStyle Congress accompanies the exhibition and brings together companies’ CEOs, scientists and environmental activists who meet manufacturers and tell them how to automate production processes and implement the new EU directive provisions. The Green TexStyle conference is a knowledge mine about ecology and sustainable development in textiles and clothing production. The Business TexStyle conference features industry experts sharing tips with aspiring entrepreneurs at presentations and lectures. The last part of the congress, Innovation TexStyle, is devoted to innovative solutions for machines, fabrics, and materials.

The Polish and CEE region market hungry for new technologies

The textile industry, which comprises the textile, clothing, leather and footwear industries, operates one of the most globalised value chains. According to the European Commission data, this industry employs 2.2 million people on the old continent, and 99.5% of companies operating in this ecosystem are small and medium-sized enterprises. These enterprises have the most challenging time competing with Global South factories; the lack of regulation there allows millions of cheap products to be made every day.

According to data from the Polish Textile Industry Association, the Polish textile industry now employs 194,000 people and is one of the largest in the country and the third most promising in Europe. This does not mean, however, that Poland’s industry does not always have to face new challenges.

- Today, we must thoroughly follow new trends and requirements; we are committed to entering a much higher technological and qualitative level. We face the great challenge of transitioning from manual to machine work. Thus, we have fewer and fewer opportunities to educate our staff; people willing to work in our industry are increasingly scarce, and we need to automate specific processes – says Ireneusz Chabrowski, president of the Polish Textile Industry Association.

Using artificial intelligence and machines that could replace people is one of the most effective methods of boosting and enhancing business development and staying afloat. Machines that operate with AI support enable the optimisation of production processes, waste reduction and energy efficiency, to name just a few domains. Furthermore, the latest developments are not on the payroll, and they get fixed monthly salaries.

Several global manufacturers already use cutting-edge solutions, such as artificial intelligence-based textile machines used by Levi Strauss & Co and Adidas, to name a few.

Targi Kielce – the innovations centre in the heart of Europe

For over three decades, the Kielce Exhibition and Congress Centre has been the industry leader - the organiser of business events, conferences and other events. Targi Kielce hosts over 70 trade fairs and nearly 400 conferences every year. Today, the centre has 90,000 square meters of exhibition space, including 36,000 in seven expo halls with all the necessary utilities – all you need for exhibition purposes. A multi-level car park for 480 cars, a congress and banquet hall for 850 people, 19 modern conference rooms and spaces for business meetings in a 57-meter observation tower are at your disposal. Targi Kielce will soon begin construction of the eighth and most advanced expo hall in Poland. The new structure will be approximately 15 metres high, 74 metres wide and 273 metres long; the construction costs are over 100 million PLN. Completion is planned for mid-2026.

Fibre2Fashion News Desk (HU)