Furthermore, one OptiMax-i Connect machine will be shown at the Bonas booth. Meanwhile, all of the state-of-the-art functionalities of Picanol’s new digital platform, PicConnect, will also be demonstrated at the event, Picanol said in a media release.

Picanol has been successfully serving the Indian market since 1956. In light of the potential and expected growth of the Indian market, Picanol decided to set up its own branch in India in early 2008. The aim behind this move was to ensure optimal proximity to the customer, in terms of both service and sales. In the meantime, Picanol India has grown into a team of 42 people, who serve its Indian customers in all of the main textile areas. Picanol India has offices situated in Coimbatore and Mumbai. Its main office is in New Delhi, which also has a print repair station that is equipped with the latest technology.

“This set-up, combined with high-performance Picanol weaving machines, has enabled us to acquire a leading position in the Indian market. Clear proof of Picanol’s dedication to the Indian market is its continuous investment in facilities and people. In this regard, we proudly opened our new head office in Delhi in April 2012 followed by further extension of office space to provide enhanced services to more customers in March 2022. We also continue to reinforce our sales and service team so that we can support our customers in the best possible way with all of the challenges they are facing,” explained Kasiviswanathan Palanisamy, director of Picanol India.

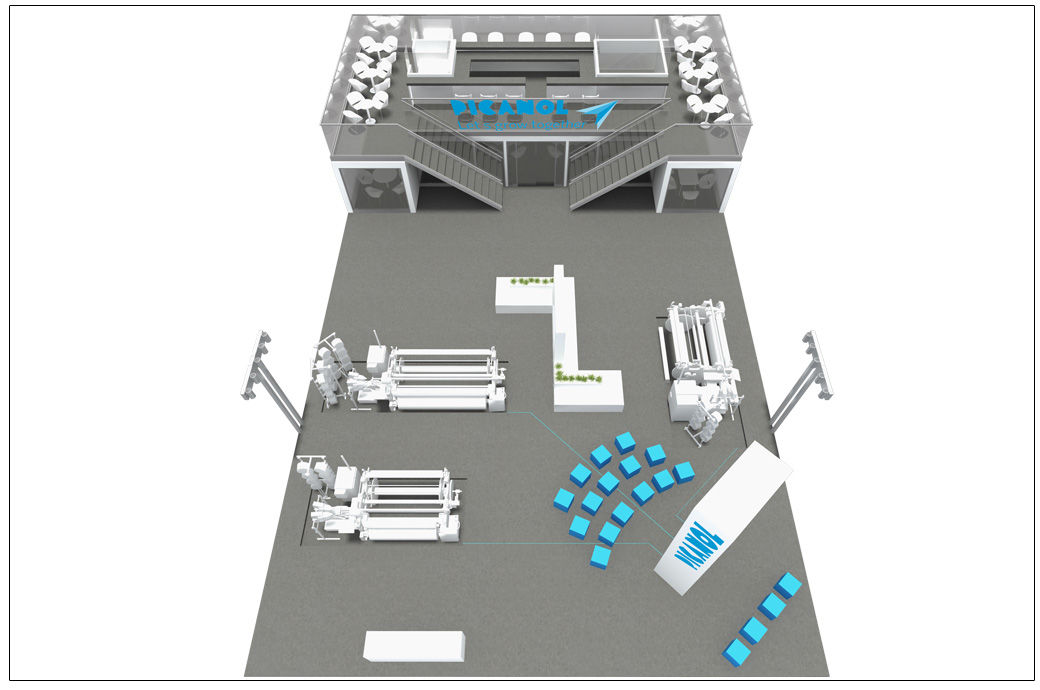

The following five Picanol weaving machines will be on display at the event: the OmniPlus-i Connect-4-P-190 Poplin, OmniPlus-i Connect-2-P-280 Ladies Wear, OmniPlus-i Connect-4-D-220 Denim, PicConnect Corner, and OptiMax-i Connect-8-J-380 (Bonas - Hall 14A - Booth 2B1).

Machine 1: The OmniPlus-i Connect-4-P-190 Poplin is proof of how a lighter fabric segment can benefit from the OmniPlus-i Connect platform. It is characterised by digitisation, maximum flexibility, and running at the highest speed.

Warp: Co Ne 60/1

Density: 165.1 ends/inch

Drawing in width: 64 inches

Weft: Co Ne 60/1

Density: 100.1 picks/inch

Highlighted features: AirMaster - Adaptive Relay Valve Drive (ARVD II Plus) - AutoSpeed - BlueBox electronic platform - BlueTouch display - Power monitoring - Prewinder Switch-Off (PSO)

Standard: BlueBox electronic platform - BlueTouch display - SUMO drive concept - Climate monitoring - Shed calculation - PicConnect enabled

Monitor package: Access control - OptiStyle - Raw material use

Smart savings package: Power monitoring - AirMaster with integrated air consumption meter - Adaptive Relay Valve Drive (ARVD II Plus)

Automation package: Pick Repair Automation (PRA II Plus) - Prewinder Switch-Off (PSO) – AutoSpeed - Harness frame stroke measurement & Shed simulation

Machine 2: The OmniPlus-i Connect-2-P-280 Ladies Wear enables weaving light filament fabrics without having to choose between speed and flexibility. Reaching the required high fabric quality standards becomes even more easy with the increased inbuilt stability of the insertion system.

Warp: Cv 75f30 den

Density: 83.8 ends/inch

Drawing in width: 96 inches

Weft: Cv 120f10 den

Density: 68.6 picks/inch

Highlighted features: SUMO drive concept - e-Leno - Fully electronic pressure settings - Sensor dashboard - Smart signal lights - LED illumination

Standard: BlueBox electronic platform - BlueTouch display - SUMO drive concept - Climate monitoring - Shed calculation - PicConnect enabled

Monitor package: Access control - OptiStyle - Raw material use

Smart savings package: Power monitoring - AirMaster with integrated air consumption meter - Adaptive Relay Valve Drive (ARVD II Plus)

Automation package: Pick Repair Automation (PRA II Plus) - Prewinder Switch-Off (PSO) - AutoSpeed - Harness frame stroke measurement & Shed simulation

Machine 3: The OmniPlus-i Connect-4-D-220 Denim is a digital loom machine that is driven by data. It relys on smart performance, keeping sustainability always in mind.

Warp: Co Ne 40/2

Density: 104.1 ends/inch

Drawing in width: 80 inches

Weft: Co Ne 20/1 + Pes/El 150 den

Density: 100.1 picks/inch

Highlighted features: SmartShed - Access control - Climate monitoring - Elsy Plus - Pick Repair Automation (PRA II Plus) - Quick Style Change (QSC) - Raw material use

Standard: BlueBox electronic platform - BlueTouch display - SUMO drive concept - Climate monitoring - Shed calculation - PicConnect enabled

Monitor package: Access control - OptiStyle - Raw material use

Smart savings package: Power monitoring - AirMaster with integrated air consumption meter - Adaptive Relay Valve Drive (ARVD II Plus)

Automation package: Pick Repair Automation (PRA II Plus) - Prewinder Switch-Off (PSO) – AutoSpeed - Harness frame stroke measurement & Shed simulation

Machine 4: The PicConnect Corner is Picanol’s digital platform for customers, offering a wide range of features from industrial IoT to service-related applications.

All of the weaving machines at Picanol’s booth will be connected to PicConnect. Live demonstrations will frequently take place throughout each day of the exhibition.

Machine 5: The OptiMax-i Connect-8-J-380 will be displayed at the Bonas Hall, 14A - Booth 2B1.

Warp: Pes 50 den

Density: 120 ends/inch

Drawing in width: 141 inches

Weft: Pes 150f72 den + lurex (Jari) 150 den

Density: 53.3 picks/inch

Fibre2Fashion News Desk (NB)