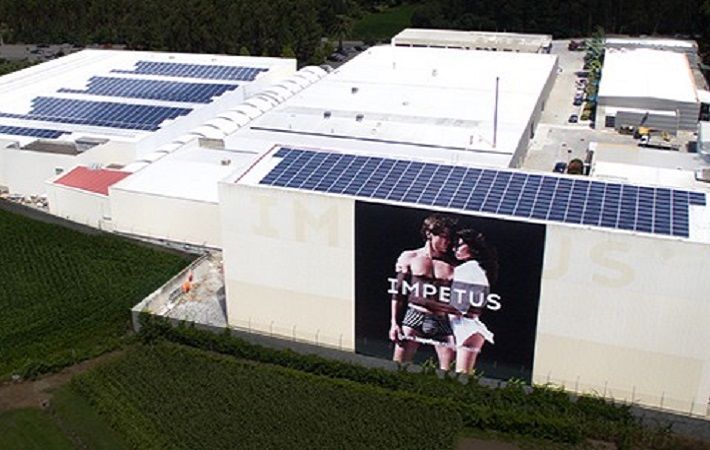

A large part of the Impetus industrial area has photovoltaic panels installed since 2013 for the sale of energy, having been recently expanded for self-consumption. About 80 per cent of the company's fleet is made up of plug-In electric and hybrid cars that use the energy produced by photovoltaic panels. The production facilities have integrated water treatment systems, monitor and control their gaseous emissions, and use biomass to produce steam and hot water, the company said in a media release.

In addition, the choice of sustainable and innovative materials, which is visible in the collections presented, is also a priority for the group. The most recent example of this is the partnership with a European spinning company, which resulted in a recycled yarn using Impetus' own textile waste from the production process – E*Retrace.

The reuse process is developed through a waste sorting system that collects and separates waste from production. Later waste is crushed, which is turned into yarn by the company’s partner and returns to Impetus to be re-incorporated into the production to make the final product.

The main goal is to contribute to the circular economy and zero waste movement, ensuring greater transparency and authenticity throughout the production process. The remaining waste that is not reused in this process is sent for reuse in other sectors of activity.

In addition to this initiative, Impetus is also working on other yarns, namely recycled ones that use post-consumer material or industrial waste mixed with virgin fibres, thus allowing to reduce the amount of water used in production and CO2 emissions into the atmosphere.

Another yarn that Impetus is incorporating in its productions is the 100 per cent carbon positive cotton yarn Good Earth Cotton – GEC. This cotton is considered the most ethical on Earth because it sequesters more carbon from the atmosphere than what is created during its entire cultivation process, and is therefore considered positive carbon, certified by independent entities.

Another innovative feature of the E*Retrace yarns and the GEC positive carbon cotton yarn is that they have an incorporated technology – Fibertrace – which makes them fully traceable, thus allowing the entire production process to be completely transparent, from the fibre to the final product. This ensures that each member of the textile supply chain can take direct responsibility for reducing the environmental impact of the global industry, allowing the end consumer to know the entire path and environmental impact of their garment.

At the same time, the Impetus group is still working on several other projects that share the common vision that a greener future is a better future, continuing to walk towards a sustainable journey and reducing our ecological footprint.

Fibre2Fashion News Desk (KD)