PrimaLoft, a leader in advanced material technology, has unveiled PrimaLoft Bio Performance Fabric, the first 100 per cent recycled, biodegradable synthetic fabric. This follows the launch of PrimaLoft Bio Insulation, also the first technology of its kind. PrimaLoft is targeting fall 2020 for consumer availability of both the biodegradable products.

The same 100 per cent recycled, biodegradable technology used in the development of PrimaLoft Bio Insulation is used in the development of PrimaLoft Bio Performance Fabric.PrimaLoft, a leader in advanced material technology, has unveiled PrimaLoft Bio Performance Fabric, the first 100 per cent recycled, biodegradable synthetic fabric. This follows the launch of PrimaLoft Bio Insulation, also the first technology of its kind. PrimaLoft is targeting fall 2020 for consumer availability of both the biodegradable products.#

"From the beginning of this process, we have always considered fabrics to be a particularly important part of the development of biodegradable materials. With this advancement, a fabric garment may now be completely returned to nature," said Mike Joyce, president and CEO of PrimaLoft. "Because we will not compromise performance, we needed to ensure that our biodegradable fibres would stand up to the rigorous process of manufacturing fabrics, while maintaining its ability to degrade. This is really a new frontier, and we are out in front, setting the standard. As we drive this approach, we will be leading the way towards significantly lessening the environmental impact of the textile industry."

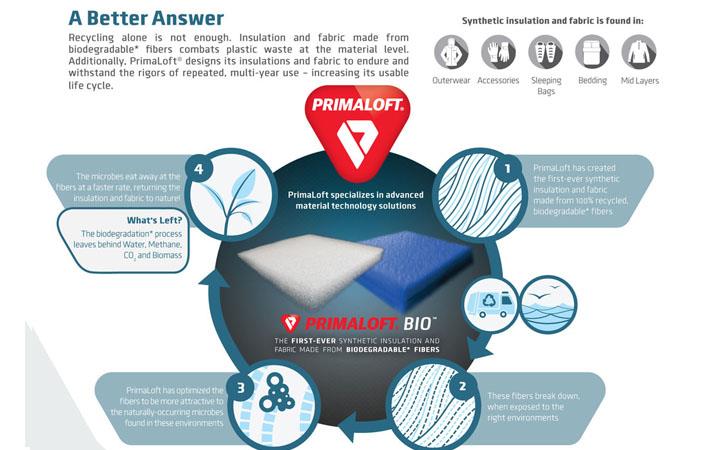

Made from 100 per cent post-consumer recycled material, PrimaLoft Bio fibres break down when exposed to specific environments – such as a landfill or the ocean. PrimaLoft has enhanced the fibres to be more attractive to the naturally-occurring microbes found in these environments. The microbes eat away at the fibres at a faster rate, returning the fabric or insulation to natural elements.

As a result, this breakthrough combats the growing problem of microplastics littering the ocean, a significant issue for the textile industry. It is estimated that half a million tons of plastic micro-fibres shed during the washing of plastic-based textiles such as polyester, nylon, or acrylic end up in the ocean every year, according to research from The Ellen MacArthur Foundation. PrimaLoft Bio fibres will only biodegrade when exposed to the naturally-occurring microbes in landfills or bodies of water, thus, the fabric remains highly durable throughout its usable life cycle in a garment.

Specific test results show 84.1 per cent biodegradation in 423 days under ASTM D5511 conditions (accelerated landfill simulation) and 55.1 per cent in biodegradation in 409 days under ASTM D6691 conditions (accelerated marine simulation).

"We never saw recycling as the final answer. We have not only been able to break the biodegradability code but, we're really setting sustainability forward," Joyce continued. "It's going to be very challenging to police the world but, what we can do is effect the properties of the fibre, so that it does no harm. This is part of our commitment to be Relentlessly Responsible."

To date, PrimaLoft has saved more than 90 million plastic bottles from landfills and transformed them into premium insulation technologies. By 2020, 90 per cent of PrimaLoft insulation products will have at least 50 per cent post-consumer recycled content, without compromising performance. (SV)

Fibre2Fashion News Desk – India