The product, which is made from the Inspire functional fabric, was developed by the Munich pioneer’s Design2Recycle team of sustainable functional textile experts, in collaboration with Swiss wear2wear co-founder Schoeller Textil. Inspire is a 100 per cent polyester, high-quality workwear fabric that features a non-PTFE, non-PFC and climate-neutral Sympatex membrane with optimal breathability to ensure a high degree of climate and wearing comfort.

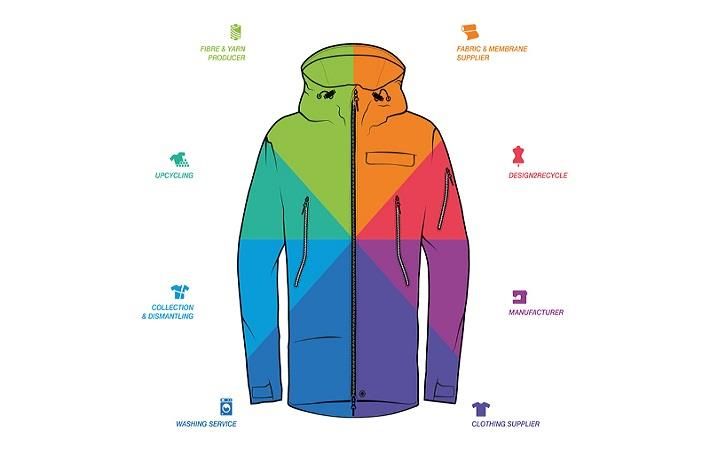

The Design2Recycle team designed the functional jacket so that it combines the best worlds of ecological and economical reuse in a single product, all without the need for time-consuming and costly separation processes. Apart from the Sympatex membrane, high value was also placed on fully reusable polyester in the selection of the materials for the jacket components (i.e cord, zippers, Velcro fasteners) in order to manufacture a recycled, unmixed polyester product that in turn can be easily fed back into the upcycling process at the end of its life cycle.

With the creation of the wear2wear industry partnership, Sympatex is pushing its explicit goal and corporate strategy of offering 100 per cent contaminant-free, recycled functional textiles, which in turn can be reused, by the year 2020. After establishing the corresponding commitment at the beginning of 2017, Sympatex raised the bar for its sustainability goals even higher in May 2019. By next year, the functional specialist will begin offering closed loop laminates made out of used textile materials in all of its business areas.

The goal within five years is for at least half of the raw materials required for its functional laminates to originate from a closed textile loop, and be reusable again. Longer term, Sympatex is committed to being fully reliant on a closed loop by 2030. This will be made possible through the development of joint efforts and industry partnerships such as wear2wear, as well as by investing in new technologies such the British startup Worn Again Technologies.

“With wear2wear, our vision is to manufacture high-quality textile products made completely from used textiles. Thanks to the consortium, we are coming one step closer to this goal each day. Each partner makes its own individual contribution to the textile loop, from the collection of old textiles, to the production of new ones. After all, only by bundling our technology know-how and our innovative services and expertise, will we be in a position to fully close the polyester loop for textiles in the near future,” said Dr. Rüdiger Fox, CEO at Sympatex Technologies GmbH. “Given that 50 per cent of the textiles from our entire industry are made from polyester, we obviously need to place our focus on this material for our journey to circular manufacturing. This is a vision that can already be turned into reality in concert with all wear2wear partners.”

As one of the worldwide leading producers, Sympatex Technologies has been a synonym for high-tech functional materials in clothing, footwear, accessories and technical fields of application since 1986. Together with selected partners, Sympatex develops, produces and distributes membranes, laminates and functional textiles as well as finished products worldwide. The Sympatex membrane is highly breathable, 100 per cent wind- and waterproof and regulates the climate. It is 100 per cent recyclable, climate-neutral, bluesign certified, and it received the ‘Oeko-Tex-Standard 100’ certificate. It is also PTFE-free and PFC-free. The technologies and procedures are based on the principles of ecological responsibility and sustainability with a special focus on the optimal carbon footprint.

Fibre2Fashion News Desk (PC)