Technical Fibre Products (TFP), a part of the James Cropper Advanced Materials Division, is proud to announce a groundbreaking advancement in the field of battery technology with the introduction of its high-performance carbon fibre nonwovens. These innovative materials, designed to significantly enhance the efficiency and durability of power generation and storage systems, represent a major step forward in the industry.

REVOLUTIONARY NONWOVEN TECHNOLOGY FOR ENHANCED ELECTROCHEMICAL PERFORMANCE

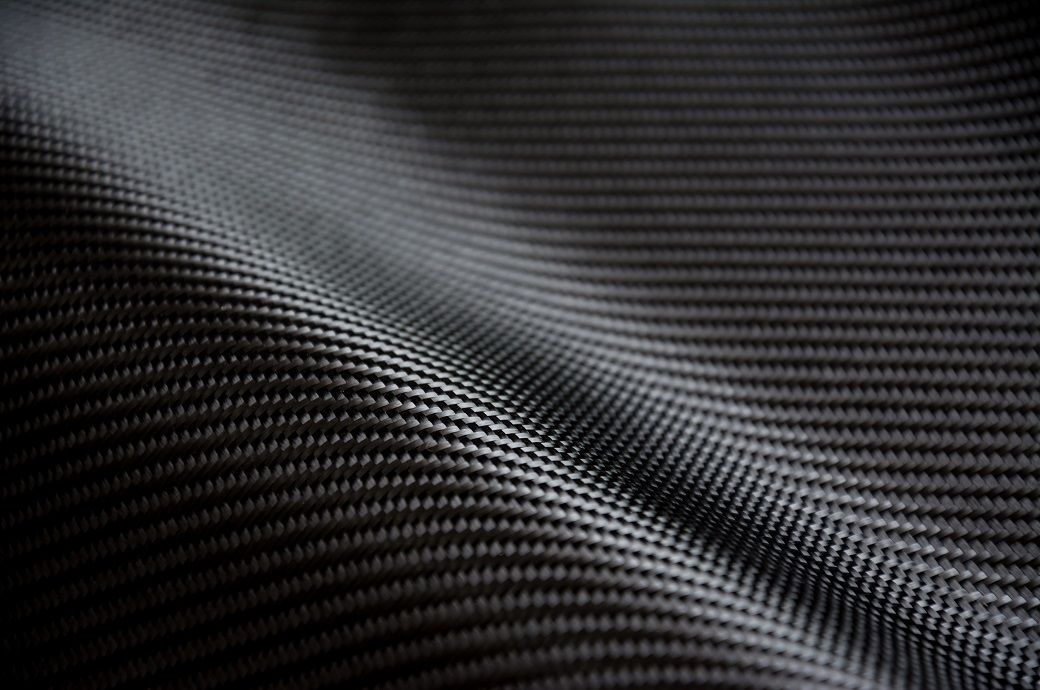

TFP's carbon fibre nonwovens are engineered using proprietary wet-laid technology, creating a highly conductive framework with exceptional surface area and porosity. This design enables a tenfold increase in electrochemical reactions, thereby improving both the power and energy density of batteries. These nonwovens serve as ideal electrodes or current collectors in flow battery systems, contributing to superior charge/discharge rates and overall battery efficiency.

COLLABORATION AND INNOVATION AT THE FOREFRONT

James Cropper Advanced Materials collaborates closely with battery manufacturers to push the boundaries of power and energy device technology. The nonwovens, featuring activated carbon fibre networks, deliver high C-rate capabilities and are customizable to meet specific application requirements. This collaboration has led to the development of novel anodes and cathodes, enhancing the performance of flow batteries and other high-energy density devices.

PIONEERING SOLUTIONS FOR A SUSTAINABLE FUTURE

In addition to their role in flow batteries, TFP’s advanced materials include bromine-tolerant PtIr/C electrocatalysts for HBr redox flow batteries. These catalysts, resistant to dissolution in HBr/Br2 solutions, ensure durability and efficiency, making them a vital component in next-generation energy storage solutions.

GLOBAL REACH AND MANUFACTURING EXCELLENCE

TFP's range of products are available across Europe and the United States, with coating lines located in the UK and the US. With a capacity to manufacture 10’s of millions m² nonwovens a year, TFP is well-equipped to meet the growing demand for high-performance materials in the energy sector.

Fibre2Fashion News Desk (HU)