This new technique could create waterproof coatings for clothes out of discarded textiles – far safer for humans and the environment than current coatings, which are typically made with harsh chemicals and carcinogens.

“If we can save one piece of clothing from going into a landfill, then that will be success,” said Hinestroza, noting that Americans throw away anywhere from 80 to 100 pounds of clothing per person annually.

The metal-organic framework (MOF) used in the group’s coating can be synthesised at room temperature, using more environmentally friendly solvents (water and ethanol) and can be achieved without separation or purification of the discarded textiles, both energy-intensive processes.

Yelin Ko, a doctoral student in the field of fibre science, is the first author of UiO-66 Inspired Superhydrophobic Coatings Fabricated from Discarded Polyester/Spandex Textiles, which was published on September 21 in ACS Applied Materials and Interfaces. Hinestroza is the senior author; Tamer Uyar, associate professor of fibre science in the department of Human Centered Design (CHE), is the other co-author.

This research is an extension of work published in 2023 demonstrating that old clothing could be chemically broken down to reuse polyester compounds to create MOF particles with potential applications in fire resistance, anti-bacterial properties, or wrinkle resistance. The new work is taking this proof of concept and applying it in a direct way, as per the studt

In this work, metal-organic frameworks – unique structures pioneered in the 1990s by chemist Omar Yaghi, with whom Hinestroza collaborated on a department of Defense grant in the late 2000s – were synthesised by chemically decomposing discarded polyester textiles into a heterogenous soup containing molecules of polyester and its monomers, dyes, additives and dirt usually associated with used clothes.

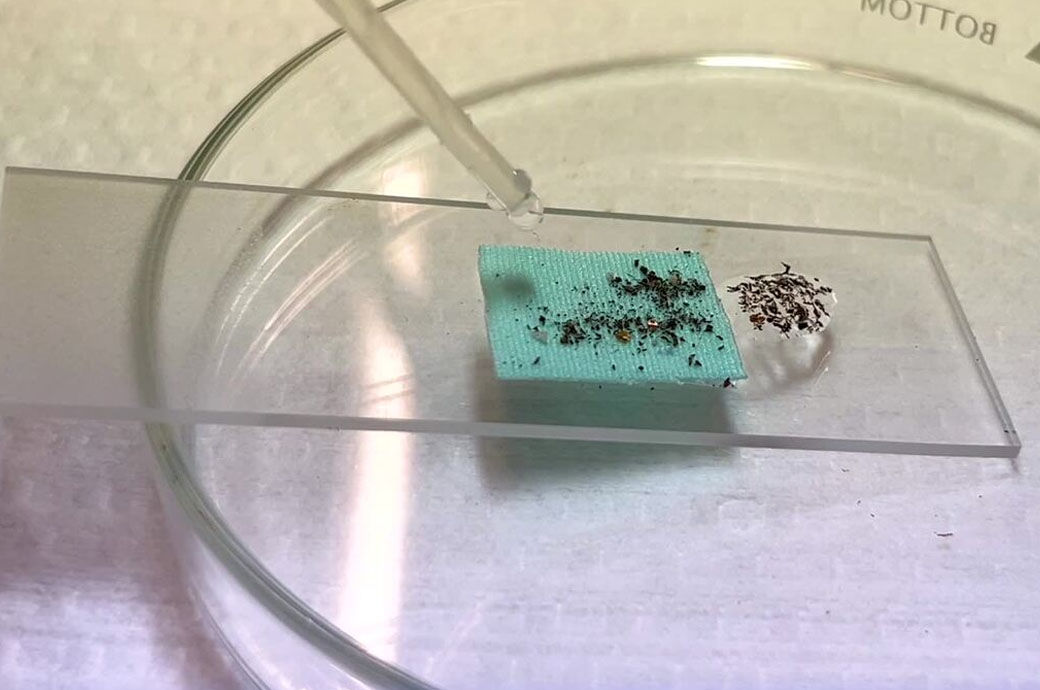

The researchers exposed discarded fabrics to an alkaline depolymerisation process to produce disodium terephthalate, a known linker for synthesis of UiO-66, a popular MOF. They conducted experiments using different amounts of ethanol, and found that with a small amount of ethanol, UiO-66 assembled on top of a polyester and spandex substrate, exhibited superhydrophobic behaviour.

The fragments of spandex, the group found, modified the otherwise hydrophilic MOF structure and made it hydrophobic. What’s more, the UiO-66 material was subjected to repeated washing and abrasion, and maintained its water resistance.

The group said this technology is one way to reduce the world’s reliance on harmful chemicals in textile manufacturing.

“We must find alternatives to fluorinated finishes, also known as ‘forever chemicals,’” Uyar said. “This study demonstrates how we can achieve functional finishes, including water-repellent and self-cleaning properties, by upcycling textile waste instead of relying on ‘forever chemicals.’”

The upcycling aspect of this work is what’s most important, Hinestroza said. “It’s very easy to blame the brands or blame the producers, but in the end, they will not produce if you don’t consume. And whatever is not being consumed is thrown away. And we want to believe that the problem ends in our garbage cans, but it doesn’t.”

This research utilised the Cornell Center for Materials Research Shared Facilities, which are supported by the National Science Foundation. Other support came from the Fulbright US student Programme, which is sponsored by the US Department of State and the Korean-American Educational Commission.

Fibre2Fashion News Desk (RR)