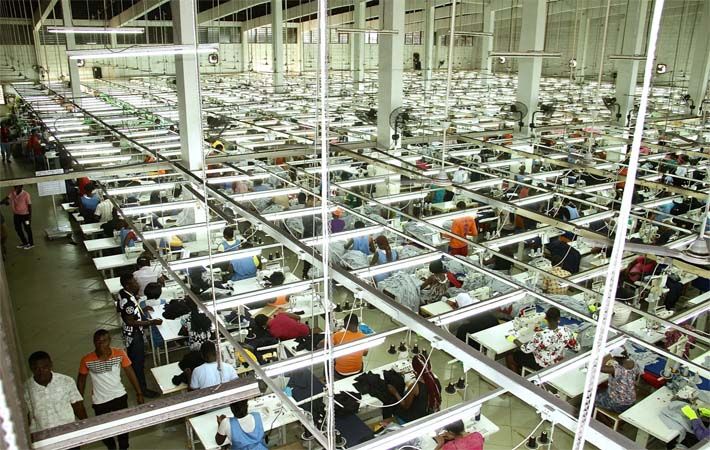

Founded on the principle that the apparel manufacturing industry has the power to drive significant, positive change to communities in emerging economies, DTRT operates a uniquely sustainable production facility in Ghana. Employing more than 2,500 people across 35 production lines, DTRT’s Ghana site produces sports and sports-lifestyle apparel – including polo shirts, fleece jackets, and t-shirts - for overseas brand customers, with a current production capacity of 4 million garments per year.

Central to DTRT’s business is the respectful treatment of workers, and the minimisation of the environmental impact of production. This high standard of sustainability is a key selling point for DTRT’s customers, making it vital for DTRT to maintain it as the company looks to dramatically increase its output - scaling to 150 production lines - and create vital manufacturing jobs in much higher volume in the near future.

To balance this ambition for precipitous growth with the company’s founding mission, in early 2021 DTRT needed a new way to maximise efficiency across both existing and planned production lines. Prior to implementing FastReactPlan, this efficiency was being held back by a reliance on manual processes and disconnected data – a combination that was also contributing to the erosion of DTRT’s margins, high incidence of employee downtime, and missed delivery deadlines. At the same time, a lack of visibility into the causes of production delays and the impact of material delays had led to an over-reliance on air freight so that orders reached overseas customers on time, Coats Digital said in a press release.

After implementing FastReactPlan, DTRT was quickly able to build a clear, systematic critical path for its materials, allowing the company to identify delays in material availability and make quick and easy adjustments to its plans with minimal disruption. Using FastReactPlan, DTRT has also been able to connect and consolidate its production data, allowing the company to track exactly how many units it needs to cut, sew, and to adjust its production and capacity plans based on accurate information.

“It was critical to us to lay the right foundations for the level of expansion we are targeting, and Coats Digital’s reputation, combined with the clear results that other manufacturers have obtained from implementing FastReactPlan made this partnership the best possible choice for us,” said Wasantha Perera, global chief operating officer of DTRT. “We plan to double our capacity annually for the next three years, and had we left our existing challenges and excess costs unaddressed, we would not have the right foundations in place to grow efficiently and cost effectively. Now, with Coats Digital’s support, we’re confident that we have the right structure to allow us to increase our margins, improve efficiency by up to 10 per cent, reduce our air freight costs and carbon footprint by up to 50 per cent, and safeguard both our world-leading sustainability standards and our strong reputation with our customers.”

“Coats Digital is extremely proud to be supporting DTRT Apparel in their ambition to become a major player in the apparel industry,” added Stuart McCready-Stocks, Coats Digital’s sales director for the EMEA region. “Not only is DTRT focused on jumpstarting the economy of developing nations and creating thousands of essential jobs, but they are committed to doing this in a safe, fair, and ethical way – all of which are principles that Coats Digital has long shared. We are thrilled that, by implementing FastReactPlan, DTRT will be able to better balance its capacities, material availability, and critical path, giving it the ability to grow with confidence and without sacrificing either efficiency or ethics. We look forward to being a continued partner on DTRT’s journey to become the go-to apparel manufacturing destination for Africa.”

Fibre2Fashion News Desk (RR)