Electronics For Imaging (EFI), developer of technologies for the manufacturing of signage, packaging, and textiles, is displaying the newest version of EFI Optitex 2D/3D CAD platform at Texprocess 2019, in hall 4, stand B41. The international trade fair for processing textile and flexible materials is being held from May 14-17, 2019, at Frankfurt, Germany.

The new software version delivers key enhancements to Optitex’s industry-leading end-to-end solution capabilities for fashion, apparel and textile, including a new and innovative print & cut solution that enables printing of all garment patterns on a single roll. The new release also features several innovative technology breakthroughs and strengthens its position as a full and sustainable end-to-end solution that helps brands and retailers get products to market faster, EFI said in a media statement.Electronics For Imaging (EFI), developer of technologies for the manufacturing of signage, packaging, and textiles, is displaying the newest version of EFI Optitex 2D/3D CAD platform at Texprocess 2019, in hall 4, stand B41. The international trade fair for processing textile and flexible materials is being held from May 14-17, 2019, at Frankfurt, Germany.#

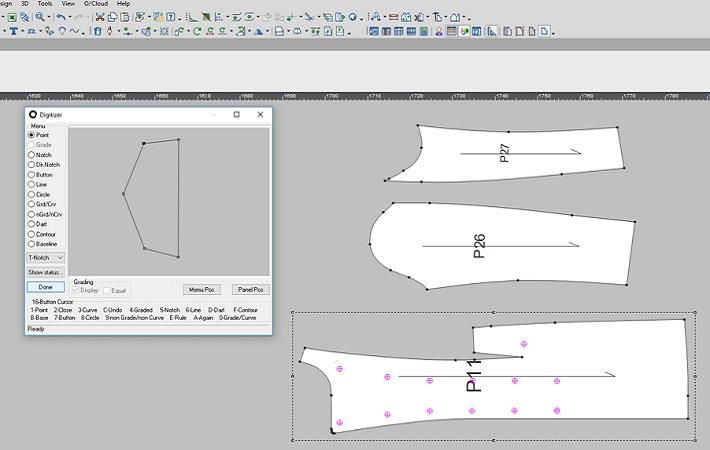

EFI Optitex software is a leading integrated 2D/3D platform that enables users to quickly create true-to-life 3D digital garments, empowering apparel and soft goods companies to revolutionise the way they develop, produce, and market their products.

“In order to respond to the fast pace of fashion and changing buying behaviours today, implementing end-to-end digital workflows is no longer a nice-to-have; it is survival. With this new Optitex release, full design-to-production preparation can be automated, enabling customers to focus on creativity, to quicken execution, and allow for the customisation required in today’s demanding market. As on-demand manufacturing of fashion and apparel continues to gain traction around the world, this new release offers the necessary efficiencies required to meet market requirements for faster time to market, accuracy, customisation and personalisation, as well as profitable and timely production of small mixed orders,” Amir Lehr, general manager, EFI Optitex said.

EFI Optitex solutions support the fashion industry’s rapid development pace and consumer demand in the digital and mobile-driven ‘see now, buy now’ era. The technology addresses retailers’ and brands’ urgent need to bring new products to market faster than ever before. It offers features such as advanced automation tools including true-to-life fabric simulation, cross-size simulation and multi-colourway-multi-angle rendering; new power tools to simplify complex stitching; improved grading; ease of design for bags and pockets; an expanded library of 150 commonly used fabrics; an all-in-one avatar solution; and an improved user interface.

The new Optitex version’s industry-changing print & cut solution for complete garment printing on a single roll enables significant savings in fabric roll inventory, with typically 15 per cent-40 per cent greater efficiency compared to traditional methods.

Fashion and apparel manufacturers also benefit from an improved nesting algorithm that increases fabric utilisation by up to 4 per cent.

Additional capabilities in the new Optitex release include advanced automation tools including true-to-life fabric simulation, cross-size simulation and multi-colourway-multi-angle rendering; power tools that simplify complex stitching and grading, including designs for bags and pockets; a gusset creation tool that simplifies definition of complex gusset shapes for bags, jackets, coats, pants and more; a rich library of more than 150 commonly-used fabrics and support for a new licensing mechanism for the Alvanon all-in-one avatar editor; and automation of routine tasks such as rendered image creation, and simulation of sized garments, avatars and poses.

The new release also enables custom views of designs for consistent and adaptable 3D sample displays for product catalogues and design review meeting, minimising the need for physical samples and costly photo shoots across the design and production workflow. (GK)

Fibre2Fashion News Desk – India