About Company

Innovation Leader in Yarn Control Feeding BTSR International S.p.A is a leader company in Advanced Yarn Control Solutions design and development. Innovation, continuous development, customer-oriented strategies are the main milestones at the basis of BTSR worldwide market leadership. BTSR stands out among its market competitors thanks to the great attention it devotes to the development of new solutions meeting the current and next future needs of the market. BTSR Team is constantly focused in providing high-tech solutions, starting from innovative ideas until the creation of a concrete ‘value’ towards the customer.

Products

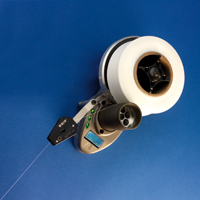

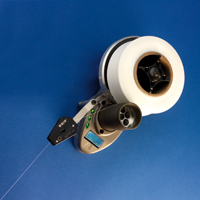

BTSR extends its sales and market penetration with ROLLING FEEDER, the Revolutionary New-Concept Device for Bare Elastomers Feeding Control, devised to impact seamless and knitting sectors habits and trends tied to bare elastomers applications. ROLLING FEEDER is a unique solution on the market, thanks to its capability to combine in a single device the flexibility and user-friendly use of BTSR Constant Tension Feeding Technology with the product top quality resulting from bare elastomeric yarns feeding at constant LFA/ speed (BTSR Patent). Easy installation, userfriendly management, retrofittable on any machine.

BTSR extends its sales and market penetration with ROLLING FEEDER, the Revolutionary New-Concept Device for Bare Elastomers Feeding Control, devised to impact seamless and knitting sectors habits and trends tied to bare elastomers applications. ROLLING FEEDER is a unique solution on the market, thanks to its capability to combine in a single device the flexibility and user-friendly use of BTSR Constant Tension Feeding Technology with the product top quality resulting from bare elastomeric yarns feeding at constant LFA/ speed (BTSR Patent). Easy installation, userfriendly management, retrofittable on any machine.

Constant Tension & Constant LFA in a single device

Thanks to the BTSR self-adaptive electronic technology, ROLLING FEEDER is infact able to work at constant tension yarn feeding during yarn ‘start/stop’ working phases (or during strong yarn pattern selections) and to automatically shift at constant LFA / speed feeding during the garment production. Based on derulè yarn reeling-off working concept, ROLLING FEEDER technology allows to eliminate yarn ‘twisting effect’ (flat yarns) and to guarantee the capability to feed elastomeric yarns at constant speed/LFA.

Get the ‘Top’ with BTSR bare elastomers feeding technology

ROLLING FEEDER System features the BTSR Patent Pending ‘Double Working Modality Master-Slave’ System (derulè at constant tension / derulè at constant LFA), with possibility to select a single or multiple devices as MASTERs and a group of units as SLAVEs, thus guaranteeing the absolute stitch matching, preventing yarn plating faults in vanisè process and guaranteeing Top quality garment production. Combined with ULTRAFEEDER devices (MASTERs) installed on the machine for background yarns feeding control, ROLLING FEEDER (SLAVEs) are able to work at a constant ‘stretch ratio’, thus guaranteeing a fully automatic constant yarn feeding / stretching and Top Quality repeatability.

A User-Friendly Solution

ROLLING FEEDER is designed for enhance operators working life by minimizing and simplify man-labour operations, thus guaranteeing the most demanding production efficiency goals achievement and getting the TOP Quality Production.

BTSR launches UNIFEEDER2, an innovative solution drastically overcoming the state-of-art of yarn storage feeding technology and destined to dramatically impact socks, hosiery and knitting textile sectors. A new concept multi-patented system featuring the new concept ‘Yarn Antitwist System’ and able to guarantee a total combined yarn feeding and storage control, thus representing the first ‘positive storage’ feeder Concept introduced on the market.

BTSR launches UNIFEEDER2, an innovative solution drastically overcoming the state-of-art of yarn storage feeding technology and destined to dramatically impact socks, hosiery and knitting textile sectors. A new concept multi-patented system featuring the new concept ‘Yarn Antitwist System’ and able to guarantee a total combined yarn feeding and storage control, thus representing the first ‘positive storage’ feeder Concept introduced on the market.

A JUMP AHEAD

UNIFEEDER2 comes with innovative unique features and high-tech functions and represents a drastic jump ahead compared with the traditional storage feeding technological offer.New concept working principles such as the BTSR patented ‘Yarn Anti-twist System’, the Anti-Gravitational Floating Ring and the Output Constant Tension Self-Adaptive Technology represent radical product innovations bringing unique benefits in terms of production quality and repeatability (constant size, yarn misplating and breakage prevention, .. ) and of unlimited styles programming.

ALL IN ONE single device

UNIFEEDER2 unique technology includes input yarn breakages and knots detection control as well as yarn tears compensation, providing real-time machine stop signaling and preventive needles breakages, yarn waste, second-rate production.UNIFEEDER2 is much more than a simple storage feeder, by providing advanced unique functions like ‘Yarn Graduation Compression’ capability (i.e for technical textile applications, sock leg, seamless,..). The possibility to real-time measure the yarn consumption (LFA) and self-compensate its variation (i.e. due to fluff accumulation in the yarn finger,..) are unique features on the market.

MORE TECHNOLOGY IN LESS SPACE, PLUG & PLAY, UNIVERSALLY RETROFITTABLE

This ‘All in One’ device features incredibly minimized size and weight (up to less 50% then traditional storage feeder), thus allowing the simplest and cost-saving installation configurations (i.e. single ring, ..). A ‘plug and play’ solution, low energy consumption, unlimited styles programming possibilities, advanced display for easy data setting and monitoring. Last but not least, UNIFEEDER2 is universally retrofittable on all types of socks, pantyhose, seamless and circular knitting machine brands by working as ‘stand alone’ device with direct connection to the machine.

FAST RETURN ON INVESTMENT

UNIFEEDER2 represent a high-profitable investment for textile operators who will implement this solution in their factory. Every Production Manager will be able to measure the correlated fast ‘Return on Investment’ (ROI) in terms of production efficiency, cost-saving and machine maintenance. UNIFEEDER2 represents a technological revolution destined to change the ‘Game Rules’ and supply an epochal change in textile market technological offer as well as in the future textile operators’ demand.

ULTRAFEEDER represents the new generation BTSR solution able to satisfy the most demanding needs in socks/hosiery and large diameter circular knitting machines, seamless, flat knitting and several looms (cotton, Raschel, labelling and narrow fabrics manufacturing, ...) applications, sewing machines.

ULTRAFEEDER represents the new generation BTSR solution able to satisfy the most demanding needs in socks/hosiery and large diameter circular knitting machines, seamless, flat knitting and several looms (cotton, Raschel, labelling and narrow fabrics manufacturing, ...) applications, sewing machines.

The new ‘Full Digital’ technology is able to realize a double control on both yarn tension feeding and yarn feeding speed, thus ensuring top performances in terms of system acceleration / deceleration dynamics, very high yarn feeding resolution measurement (0,1 mm) and drastic reduction of energy consumption.

The high motor torque at ‘zero’ speed, guarantees an extremely control precision even when yarns are fed at very high tensions (up to 100 gr.) at simultaneous very low speed (0,1 mt/min.), without any pre-feeding device is needed; in the same way it can guarantee very low yarn feeding tensions (0,2 gr) at simultaneous very high speed (1500 mt/min).

TOP Flexibility, thanks to ULTRAFEEDER capability to work with all types of yarns: elastomers (thin bare, covered, interlaced (11,17 Dtex), rigid yarns (nylon, cotton, wool, polyester, ...) and technical yarns (polyester, polypropylene, ...).

The Universal System ‘UNICO & ULTRAFEEDER’

UNICO (‘UNIversal tension COntrol’) represents the BTSR new-concept device, combinable with ULTRAFEEDER, able to overcome the state-of-art technology and all limits of storage feeding and positive feeding devices, thus representing a revolutionary universal solution for hosiery and knitting sectors operators.

Thanks to its fully integrated electronic system, UNICO allows to dynamically compensate sudden and high yarn absorption variations, by instantaneously featuring both 'Positive Yarn Constant Tension' Control and 'Yarn Storage & Release' capabilities (BTSR® Patent).

'UNICO & ULTRAFEEDER' is a unique solution performing total yarn feeding control of all working knitting applications even in very extreme operational conditions: socks machines (patterns, terry / half terry, toe and heel, ...), pantyhose / seamless (patterns, very complex selections, ...), large diameter circular machines (jacquard, striper jacquard, ...), flat knitting machines and cotton looms.

Technical Features:

- Programmable tension 0,2 gr. ÷ 100 gr.

- Feeding speed till 1500 mt/min (@ 24V/36 V).

- New ‘APPLICATIONS’ function: directly visualize and select the application of interest (socks, hosiery, seamless, medical, knitting, Raschel, ...), avoiding any manual parameter setting operation by the user.

- INC/DEC function: possibility to INCrease or DECrease gradually the yarn tension with a resolution of 0,1 gr.

- LFA function: exact yarn consumption measuring (Length Yarn Absorption) with resolution of 0,1 mt.

- LFA Self-Learning function (in combination with SMART MATRIX Terminal): yarn consumption self-learning, control and automatic compensation; automatic machine stop in case of LFA error bigger than the programmed tolerance (BTSR® Patent).

- TARGET function: possibility to set a production target in meters with the relative automatic machine stop.

- New AUTO OFF-SET Function: automatic loading cell self-calibration (BTSR® Patent).

BTSR extends its sales and market penetration with ROLLING FEEDER, the Revolutionary New-Concept Device for Bare Elastomers Feeding Control, devised to impact seamless and knitting sectors habits and trends tied to bare elastomers applications. ROLLING FEEDER is a unique solution on the market, thanks to its capability to combine in a single device the flexibility and user-friendly use of BTSR Constant Tension Feeding Technology with the product top quality resulting from bare elastomeric yarns feeding at constant LFA/ speed (BTSR Patent). Easy installation, userfriendly management, retrofittable on any machine.

BTSR extends its sales and market penetration with ROLLING FEEDER, the Revolutionary New-Concept Device for Bare Elastomers Feeding Control, devised to impact seamless and knitting sectors habits and trends tied to bare elastomers applications. ROLLING FEEDER is a unique solution on the market, thanks to its capability to combine in a single device the flexibility and user-friendly use of BTSR Constant Tension Feeding Technology with the product top quality resulting from bare elastomeric yarns feeding at constant LFA/ speed (BTSR Patent). Easy installation, userfriendly management, retrofittable on any machine. BTSR launches UNIFEEDER2, an innovative solution drastically overcoming the state-of-art of yarn storage feeding technology and destined to dramatically impact socks, hosiery and knitting textile sectors. A new concept multi-patented system featuring the new concept ‘Yarn Antitwist System’ and able to guarantee a total combined yarn feeding and storage control, thus representing the first ‘positive storage’ feeder Concept introduced on the market.

BTSR launches UNIFEEDER2, an innovative solution drastically overcoming the state-of-art of yarn storage feeding technology and destined to dramatically impact socks, hosiery and knitting textile sectors. A new concept multi-patented system featuring the new concept ‘Yarn Antitwist System’ and able to guarantee a total combined yarn feeding and storage control, thus representing the first ‘positive storage’ feeder Concept introduced on the market. ULTRAFEEDER represents the new generation BTSR solution able to satisfy the most demanding needs in socks/hosiery and large diameter circular knitting machines, seamless, flat knitting and several looms (cotton, Raschel, labelling and narrow fabrics manufacturing, ...) applications, sewing machines.

ULTRAFEEDER represents the new generation BTSR solution able to satisfy the most demanding needs in socks/hosiery and large diameter circular knitting machines, seamless, flat knitting and several looms (cotton, Raschel, labelling and narrow fabrics manufacturing, ...) applications, sewing machines.