Message from Dr. Masahiro Shima - President

By far the biggest occasion for Shima Seiki in 2015 is the 20th Anniversary celebration of WHOLEGARMENT® knitting.

In Japan, one reaches adulthood at age 20. WHOLEGARMENT® has also come of age. And just as a 20-year old is ready to take on new responsibilities and begin contributing to society, WHOLEGARMENT® is also ready to take on an instrumental role in mainstream production and contribute significantly more to the knitting industry. In fact, WHOLEGARMENT® is already recognized as having revitalized several local industries worldwide by helping them regain competitiveness. With fully developed technology and a sufficiently matured market, the time has come for WHOLEGARMENT® to take center stage in the coming age.

We celebrate this occasion, together with another major event. WHOLEGARMENT® was first introduced at the 1995 International Textile Machinery (ITMA) exhibition. As this was the last time ITMA was hosted in Milan, the return of ITMA to Milan in 2015 is therefore the perfect occasion to observe this milestone. Furthermore, it so happens that the central theme at ITMA 2015 is “Sustainable Innovation.” Minimizing resources by eliminating wasted yarn, WHOLEGARMENT® is the most environmentally friendly method of garment manufacturing to date. What better theme with which to recognize 20 years of sustainable fashion?

After two decades, WHOLEGARMENT® is still in a league of its own. No one else comes close to matching our technology, or our dedication. Continuous research and development is urged on not by competition, but inspired by our own commitment to the success of the knitting industry.

We look forward to seeing you at our booth at ITMA 2015. Whether you are looking for a new business angle or a way to secure long-term success, you will surely find the right solution to benefit you now, and far beyond 2015.

About us

Shima Seiki Mfg., Ltd. of Wakayama, Japan is a leading manufacturer in the computerized flatbed knitting machine industry. With complete systems integration from planning, production to sales promotion and retail sales, Shima Seiki has been dedicating its products and services to the knitting industry worldwide through the latest in computerized knitting technology. Shima Seiki is also the pioneer in complete garment manufacturing technology—called WHOLEGARMENT®— wherein a knitted garment is produced in its entirety on the knitting machine without the need for linking or sewing afterward. Since its commercial introduction in 1995, Shima Seiki has been the undisputed leader in WHOLEGARMENT® knitting technology with 30 years of on-going research and 20 years of proprietary field experience and know-how, not to mention over 2,000 related patents and patents pending worldwide.

Corporate Motto

Ever Onward

Shima Seiki strives to maintain a spirit of tireless challenge, with continuous innovation to develop products that satisfy customer needs.

Certificiate

Shima Seiki has ISO9001 Certification for Design and Manufacturing of its design systems.

Core Business

Development, manufacture, sales and service of WHOLEGARMENT® knitting machines, computerized flat knitting machines, glove and sock knitting machines, computer graphic design systems, pattern CAD systems, computerized CAM machines (NC cutting machines), textile printing machines and other related peripherals.

Products

WholeGarment® Knitting Machines

MACH2X

MACH2®X is Shima Seiki’s flagship WHOLEGARMENT® knitting machine that features Shima Seiki’s original SlideNeedle™ on four needle beds. It can knit beautifully shaped, high-quality WHOLEGARMENT®products that conform to the body for improved comfort and a more elegant silhouette. As the “MACH” name suggests, speed and productivity are dramatic. MACH2®X achieves a maximum knitting speed of 1.6 meters per second. The R2CARRIAGE® System furthermore permits quicker carriage returns for higher efficiency per knitted course. Split Stitch technique also allows efficient knitting by eliminating empty courses. Furthermore, the latest 18L gauge version provides very high productivity when knitting ultrafine gauge garments. It also allows for tighter fabric especially for ribs, contributing to higher-quality WHOLEGARMENT® items. Dramatic improvements in both quality and productivity make the MACH2®X the ideal machine for high-quality ultrafine gauge WHOLEGARMENT® production.

MACH2®X is Shima Seiki’s flagship WHOLEGARMENT® knitting machine that features Shima Seiki’s original SlideNeedle™ on four needle beds. It can knit beautifully shaped, high-quality WHOLEGARMENT®products that conform to the body for improved comfort and a more elegant silhouette. As the “MACH” name suggests, speed and productivity are dramatic. MACH2®X achieves a maximum knitting speed of 1.6 meters per second. The R2CARRIAGE® System furthermore permits quicker carriage returns for higher efficiency per knitted course. Split Stitch technique also allows efficient knitting by eliminating empty courses. Furthermore, the latest 18L gauge version provides very high productivity when knitting ultrafine gauge garments. It also allows for tighter fabric especially for ribs, contributing to higher-quality WHOLEGARMENT® items. Dramatic improvements in both quality and productivity make the MACH2®X the ideal machine for high-quality ultrafine gauge WHOLEGARMENT® production.

SWG-Mini

Shima Seiki’s lineup of compact WHOLEGARMENT® knitting machines, known as the “SWG®Mini” series, is now in its much-improved 3rd generation. Featuring our renowned SlideNeedle on a 10-, 16-, 24- and 36-inch wide needlebed respectively, the SWG®021N2, SWG®041N2, SWG®061N2 and SWG®091N2 are capable of producing a range of fashion accessories from gloves, socks, hats, mufflers, neck-ties and other small items, as well as childrenswear and even leggings and tanktops, all in their entirety, with no sewing or linking required*. As a result, the usable range of a given yarn can be expanded to include coordinated items from head to toe for all ages. The new SWG®-N2 series features the proven R2CARRIAGE® system for higher productivity. A larger number of yarn carriers and holding hooks for yarn cutting, as well as a separate yarn holder with increased capacity allows for even more flexibility in multi-color knitting. In addition to their established reputation in the fashion industry, SWG®021N2, SWG®041N2, SWG®061N2 and SWG®091N2 are also capable machines for technical textiles, such as industrial material, sports, medicine and safety, expanding your business potential far beyond present limits.

Shima Seiki’s lineup of compact WHOLEGARMENT® knitting machines, known as the “SWG®Mini” series, is now in its much-improved 3rd generation. Featuring our renowned SlideNeedle on a 10-, 16-, 24- and 36-inch wide needlebed respectively, the SWG®021N2, SWG®041N2, SWG®061N2 and SWG®091N2 are capable of producing a range of fashion accessories from gloves, socks, hats, mufflers, neck-ties and other small items, as well as childrenswear and even leggings and tanktops, all in their entirety, with no sewing or linking required*. As a result, the usable range of a given yarn can be expanded to include coordinated items from head to toe for all ages. The new SWG®-N2 series features the proven R2CARRIAGE® system for higher productivity. A larger number of yarn carriers and holding hooks for yarn cutting, as well as a separate yarn holder with increased capacity allows for even more flexibility in multi-color knitting. In addition to their established reputation in the fashion industry, SWG®021N2, SWG®041N2, SWG®061N2 and SWG®091N2 are also capable machines for technical textiles, such as industrial material, sports, medicine and safety, expanding your business potential far beyond present limits.

3D Apparel Design Workstation

SDS®-ONE APEX3

SDS®-ONE APEX3

Drawing from years of experience and know-how as a world leader in fashion technology, Shima Seiki has created a design system that goes far beyond the simple patterning and programming available form the competition. With powerful proprietary hardware and industry-specific software developed in-house, no other design system even comes close to SDS®-ONE APEX3.

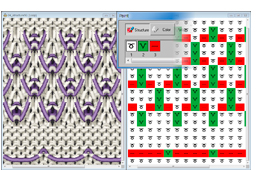

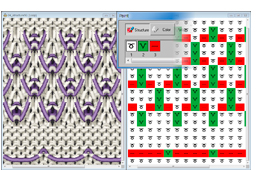

FLAT KNITTING

APEX3 can be used to design flat knitting patterns including structure patterns, intarsia patterns and jacquard patterns. It can also perform realistic simulation of yarn such as mohair yarn, slub yarn and shiny yarn, taking into account plating, number of thread take-ups and counts. It also improves production efficiency with a database of more than 1,000 structure patterns, which are linked with the KnitCAD® software for Shima Seiki knitting machines. APEX3 offers comprehensive support for each stage in the flat knitting supply chain, from knit planning, pattern design and colorway evaluation to production and even sales promotion. Furthermore, Ultra-realistic simulation capability allows APEX3 to minimize the costly time- and resourceconsuming sample-making process through Virtual Sampling.

CIRCULAR KNITTING

APEX3 can be used to design circular knit fabric patterns including stripes and jacquard patterns. It can also produce a variety of structure patterns for single-knit fabrics such as jersey and tuck patterns, as well as double-knit fabrics such as rib fabrics. Raised nap fabrics and prints can also be simulated. APEX3 offers comprehensive support for everything from product planning, pattern development, colorways and fabric simulation to output of circular knit CAD bitmap data and generation of sales promotion material.

APEX3 can be used to design circular knit fabric patterns including stripes and jacquard patterns. It can also produce a variety of structure patterns for single-knit fabrics such as jersey and tuck patterns, as well as double-knit fabrics such as rib fabrics. Raised nap fabrics and prints can also be simulated. APEX3 offers comprehensive support for everything from product planning, pattern development, colorways and fabric simulation to output of circular knit CAD bitmap data and generation of sales promotion material.

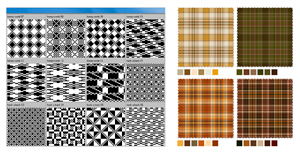

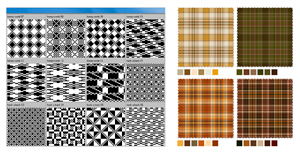

TEXTILE

APEX3 can be used to design textile patterns including stripes and check patterns, dobby patterns, multiple weaves and jacquard patterns. APEX3 offers comprehensive support for everything from textile product planning, pattern production and evaluation of colorways to output of instruction sheets, creation of product images and sales promotion.

APEX3 can be used to design textile patterns including stripes and check patterns, dobby patterns, multiple weaves and jacquard patterns. APEX3 offers comprehensive support for everything from textile product planning, pattern production and evaluation of colorways to output of instruction sheets, creation of product images and sales promotion.

PRINT

APEX3 can be used to produce colorways in single-color, gradation, shading as well as full-color. In addition to highly efficient color specification using the built-in PANTONE database and color meter, the automatic colorway feature can instantly produce a variety of color schemes for evaluation under a given theme or other requirement. APEX3 is also equipped with various pattern production tools for planning and creating original designs. Comprehensive support is available, from pattern production, repeats and colorways as well as color separation and fabric production, to product simulation and sales promotion.

MACH2®X is Shima Seiki’s flagship WHOLEGARMENT® knitting machine that features Shima Seiki’s original SlideNeedle™ on four needle beds. It can knit beautifully shaped, high-quality WHOLEGARMENT®products that conform to the body for improved comfort and a more elegant silhouette. As the “MACH” name suggests, speed and productivity are dramatic. MACH2®X achieves a maximum knitting speed of 1.6 meters per second. The R2CARRIAGE® System furthermore permits quicker carriage returns for higher efficiency per knitted course. Split Stitch technique also allows efficient knitting by eliminating empty courses. Furthermore, the latest 18L gauge version provides very high productivity when knitting ultrafine gauge garments. It also allows for tighter fabric especially for ribs, contributing to higher-quality WHOLEGARMENT® items. Dramatic improvements in both quality and productivity make the MACH2®X the ideal machine for high-quality ultrafine gauge WHOLEGARMENT® production.

MACH2®X is Shima Seiki’s flagship WHOLEGARMENT® knitting machine that features Shima Seiki’s original SlideNeedle™ on four needle beds. It can knit beautifully shaped, high-quality WHOLEGARMENT®products that conform to the body for improved comfort and a more elegant silhouette. As the “MACH” name suggests, speed and productivity are dramatic. MACH2®X achieves a maximum knitting speed of 1.6 meters per second. The R2CARRIAGE® System furthermore permits quicker carriage returns for higher efficiency per knitted course. Split Stitch technique also allows efficient knitting by eliminating empty courses. Furthermore, the latest 18L gauge version provides very high productivity when knitting ultrafine gauge garments. It also allows for tighter fabric especially for ribs, contributing to higher-quality WHOLEGARMENT® items. Dramatic improvements in both quality and productivity make the MACH2®X the ideal machine for high-quality ultrafine gauge WHOLEGARMENT® production. Shima Seiki’s lineup of compact WHOLEGARMENT® knitting machines, known as the “SWG®Mini” series, is now in its much-improved 3rd generation. Featuring our renowned SlideNeedle on a 10-, 16-, 24- and 36-inch wide needlebed respectively, the SWG®021N2, SWG®041N2, SWG®061N2 and SWG®091N2 are capable of producing a range of fashion accessories from gloves, socks, hats, mufflers, neck-ties and other small items, as well as childrenswear and even leggings and tanktops, all in their entirety, with no sewing or linking required*. As a result, the usable range of a given yarn can be expanded to include coordinated items from head to toe for all ages. The new SWG®-N2 series features the proven R2CARRIAGE® system for higher productivity. A larger number of yarn carriers and holding hooks for yarn cutting, as well as a separate yarn holder with increased capacity allows for even more flexibility in multi-color knitting. In addition to their established reputation in the fashion industry, SWG®021N2, SWG®041N2, SWG®061N2 and SWG®091N2 are also capable machines for technical textiles, such as industrial material, sports, medicine and safety, expanding your business potential far beyond present limits.

Shima Seiki’s lineup of compact WHOLEGARMENT® knitting machines, known as the “SWG®Mini” series, is now in its much-improved 3rd generation. Featuring our renowned SlideNeedle on a 10-, 16-, 24- and 36-inch wide needlebed respectively, the SWG®021N2, SWG®041N2, SWG®061N2 and SWG®091N2 are capable of producing a range of fashion accessories from gloves, socks, hats, mufflers, neck-ties and other small items, as well as childrenswear and even leggings and tanktops, all in their entirety, with no sewing or linking required*. As a result, the usable range of a given yarn can be expanded to include coordinated items from head to toe for all ages. The new SWG®-N2 series features the proven R2CARRIAGE® system for higher productivity. A larger number of yarn carriers and holding hooks for yarn cutting, as well as a separate yarn holder with increased capacity allows for even more flexibility in multi-color knitting. In addition to their established reputation in the fashion industry, SWG®021N2, SWG®041N2, SWG®061N2 and SWG®091N2 are also capable machines for technical textiles, such as industrial material, sports, medicine and safety, expanding your business potential far beyond present limits. SDS®-ONE APEX3

SDS®-ONE APEX3 APEX3 can be used to design circular knit fabric patterns including stripes and jacquard patterns. It can also produce a variety of structure patterns for single-knit fabrics such as jersey and tuck patterns, as well as double-knit fabrics such as rib fabrics. Raised nap fabrics and prints can also be simulated. APEX3 offers comprehensive support for everything from product planning, pattern development, colorways and fabric simulation to output of circular knit CAD bitmap data and generation of sales promotion material.

APEX3 can be used to design circular knit fabric patterns including stripes and jacquard patterns. It can also produce a variety of structure patterns for single-knit fabrics such as jersey and tuck patterns, as well as double-knit fabrics such as rib fabrics. Raised nap fabrics and prints can also be simulated. APEX3 offers comprehensive support for everything from product planning, pattern development, colorways and fabric simulation to output of circular knit CAD bitmap data and generation of sales promotion material. APEX3 can be used to design textile patterns including stripes and check patterns, dobby patterns, multiple weaves and jacquard patterns. APEX3 offers comprehensive support for everything from textile product planning, pattern production and evaluation of colorways to output of instruction sheets, creation of product images and sales promotion.

APEX3 can be used to design textile patterns including stripes and check patterns, dobby patterns, multiple weaves and jacquard patterns. APEX3 offers comprehensive support for everything from textile product planning, pattern production and evaluation of colorways to output of instruction sheets, creation of product images and sales promotion.