Hundreds of billions of plastic bottles go as waste every year after it has served its purpose. Polygenta we love plastic bottles. We view them as the fruit of brilliant human ingenuity and of large capital investment. Do we really consider the bottle as a waste when we drink from it? Instead, we believe that these bottles are a formidable source of plastics which can be recycled back to bottles, yarns and fabrics or films. So, Polygenta exist because we own a technology and a large commercial plant (in Nashik, Maharashtra, India) where we convert every day 1.5 million of clear and coloured bottles. Our recycled, sustainable polyester is cost competitive with its "virgin" equivalent, produced by the petrochemical industry from oil. We believe that low cost is necessary to sustain an environmentally friendly business and products. Our technology allows us to be low cost producer of recycled polyester, with a level of quality assurance and performance comparable to the "virgin" polyester, because we can scale our plants and convert cheap polyester waste (such as coloured bottles or fabric waste).

Hundreds of billions of plastic bottles go as waste every year after it has served its purpose. Polygenta we love plastic bottles. We view them as the fruit of brilliant human ingenuity and of large capital investment. Do we really consider the bottle as a waste when we drink from it? Instead, we believe that these bottles are a formidable source of plastics which can be recycled back to bottles, yarns and fabrics or films. So, Polygenta exist because we own a technology and a large commercial plant (in Nashik, Maharashtra, India) where we convert every day 1.5 million of clear and coloured bottles. Our recycled, sustainable polyester is cost competitive with its "virgin" equivalent, produced by the petrochemical industry from oil. We believe that low cost is necessary to sustain an environmentally friendly business and products. Our technology allows us to be low cost producer of recycled polyester, with a level of quality assurance and performance comparable to the "virgin" polyester, because we can scale our plants and convert cheap polyester waste (such as coloured bottles or fabric waste).

We believe that sustainable models of growth will be rewarded in the near future, as quality management processes have been introduced 40 years ago by the Japanese industry in particular and have become the norm. Our goal is to add a dimension of sustainability to the growth of the virgin polyester industry: we see ourselves as an enabler of the existing polyester business with a humble but tangible contribution to its sustainable growth.

Look at our recycled yarns, touch the fabrics made from our yarns - we are in for success, a formidable success, which we build on our core values of humility, respect and honesty.

About Polygenta

Polygenta Technologies Limited (PTL) is a leading manufacturer of Polyester Filament Yarn (PFY) using post-consumer PET bottles (i.e. a high-grade polyester) as its feedstock. Polygenta’s plant located in Nashik (Maharashtra, India) converts 1.5 million bottles per day to produce roughly 10,000 MTs per annum of sustainable premium PFY. PTL also has plans to expand this capacity significantly.

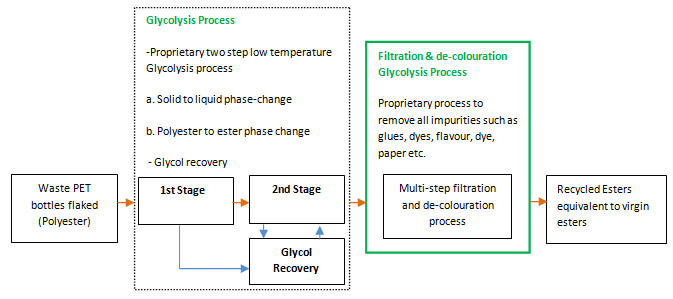

Company achieve this with its proprietary “ReNEW” process. ReNEW chemically “de-constructs” the long chain “poly-ester” hard plastic that PET bottles are made of into their original “building blocks” of individual esters in liquid form. After high purity filtration of this liquid, these esters can be substituted for high-grade conventional polyester petrochemical feedstock refined from crude oil (PTA and MEG).

With its unique approach to recycling PET bottles, fundamentally different from the prevalent “mechanical technologies”, ReNEW has a number of advantages in terms of energy, effluent, water use, and product quality. Based on an independent life cycle analysis, the primary energy demand to manufacture polyester polymer using the ReNEW process is lower than consumed when conventional virgin petrochemical feedstock is used.