Sustainability requires meeting the needs of the present without compromising

the ability of future generations to meet their own needs. FiberVisions is

committed to safe operations and responsible stewardship of the environment. We

believe that our business must be a safe place to work, our facilities must be

good neighbors in their communities, and our operations and products should be

continuously improved to reduce their impact on the environment.

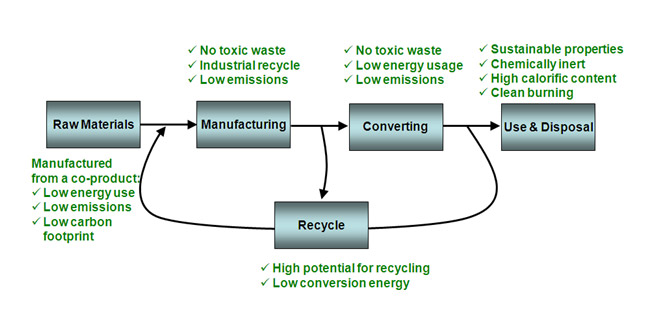

Our concern for sustainable development has led us to examine and manage the

environmental impact of our products throughout their entire life cycle-from

raw materials through final use and disposal. Here’s how our fibers make

life better and minimize their impact on the environment :

- Raw Materials: Of the major synthetic fibers, polypropylene (PP) is the only one that is created as a by-product-with lower greenhouse gas emissions and lower energy use than other fiber resins.

- Manufacturing: Making PP fiber from polypropylene is a process with low impact on the environment-no toxic waste, no toxic emissions, no fluorocarbons and no halogens.

- Converting: The manufacture of products from PP staple fiber has low environmental impact:

- Low melting point reduces the amount of energy needed to create products.

- Low moisture pickup requires less energy to dry products (if needed).

- Scrap/waste from converting operations is recyclable/reusable in manufacturing operations.

- No toxic emissions or wastes.

- Use in Product Manufacturing: PP fiber has many properties that contribute to sustainable use. PP fiber is:

- Chemically inert, so it doesn’t break down with harmful effects on health or the environment.

- Low in density, so less of it is needed than other fibers to make products.

- Durable, so products using it can last longer and don’t need rapid replacement.

-

Easily cleaned without high energy or environmentally unfriendly methods.

- Disposal: PP staple fiber has a very high calorific value when incinerated as part of a mixed waste stream, providing a high energy value for the amount of CO2 emitted. It’s also clean burning, with no toxic emissions.

Lifecycle Perspective of Polyolefin Fibers Fibers that make life better and minimize impact on the environment

Mono and Bicomponent Fibers:

FiberVisions develops, manufactures and markets polyolefin fibers for nonwoven, textile and industrial applications. Our fibers are used in nonwovens made by carding, wet lay and air laid web formation processes and consolidated by thermal bonding, air through bonding, needle punching and spunlacing.

Our capabilities include:

- Typical titer range: 1-20 dtex

- PP and PE monocomponent fibers

- PP or PET core, PE sheath bicomponent fibers

- Hydrophilic, durably hydrophilic, hydrophobic, other functional finishes

- Natural (bright), white, or pigmented fibers

- Various fiber designs, including shaped fibers

- Additives for enhanced performance

- Range of fiber lengths

- Short cut: 3 - 30 mm

- Staple: 25 - 128 mm